Browse Our Collection

Get instant quotes that fit your budget perfectly.

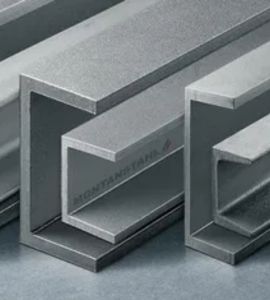

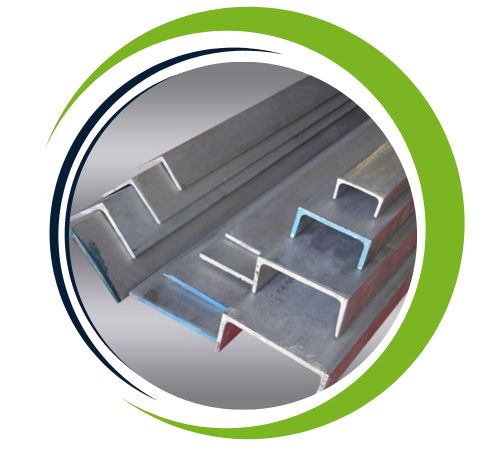

Stainless Steel 310 Channel is a top-notch austenitic stainless steel product crafted for outstanding resistance to heat, oxidation, and corrosion. With a high chromium content (24–26%) and nickel (19–22%), this material offers remarkable thermal stability, scaling resistance, and toughness, especially in high-temperature settings. These channels are meticulously manufactured to ensure consistent dimensions, a smooth surface finish, and robust structural integrity, making them perfect for use in industrial furnaces, heat exchangers, and high-temperature structural frameworks. The combination of strength, durability, and corrosion resistance in Stainless Steel 310 Channels makes them a go-to choice for industries like power generation, chemical processing, and petrochemicals, where reliable performance under extreme thermal conditions is a must.

The composition of Stainless Steel 310 Channel primarily includes iron, chromium (24–26%), and nickel (19–22%), along with trace elements of carbon, manganese, and silicon. Its mechanical properties boast a tensile strength of about 515–720 MPa, a yield strength around 205 MPa, and impressive elongation, which contributes to its toughness and flexibility. Thanks to its austenitic microstructure, it offers excellent formability, weldability, and resistance to oxidation, scaling, and thermal fatigue. The high-temperature stability and mechanical strength of 310 stainless steel channels make them ideal for structural and fabrication applications in challenging thermal and corrosive environments.

| Standard | ASTM A276, ASTM A479 / ASME SA276, ASME SA479 |

| Condition | HRAP |

| Size Range | Base: 80 to 150 mm Side: 40 to 75 mm |

| Thickness | 5 to 6 mm (depending on size) |

| Grades | 304, 316 |

| Processing | Bar cutting |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|---|

| SS 304 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | – | 8 – 11 |

| SS 304L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.03 max | 18 – 20 | – | 8 – 13 |

| SS 316 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 11.00 – 14.00 |

| SS 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 1.0 max | 16.00 – 18.00 | 16.00 – 18.00 | 10.00 – 14.00 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Yunus Sheets and Plates based in Istanbul, Turkey, is a leading supplier and stockist of high-quality metal products, including Sheets, Plates, Coils, Foils, Angles, Channels, Circles, and Slitting Coils, all offered with exceptional service and tailored to meet our customers specific requirements. With a focus on delivering superior products, we cater to a wide range of industries, providing reliable solutions for diverse applications. Our extensive inventory includes Known for our unique finishing techniques and commitment to quality. We are dedicated to ensuring customer satisfaction through dependable service and top-notch products.

Stainless Steel 310 Channel offers exceptional high-temperature resistance, making it ideal for applications exposed to extreme heat. Its high chromium and nickel content provide outstanding oxidation and corrosion resistance, ensuring long-term durability in harsh environments. The alloy’s ability to maintain strength and stability at temperatures up to 1,100°C (2,012°F) makes it perfect for use in high-heat applications such as furnaces and heat exchangers. Stainless Steel 310 is also highly resistant to scaling, ensuring reliable performance in aggressive environments. Additionally, it offers excellent weldability and formability for ease of fabrication.

Yes, we offer custom sizes for Stainless Steel 310 Channel to meet specific project needs. Our team at Yunus Sheets and Plates is dedicated to providing tailored solutions for all your requirements. For more details, contact us at sales@aaronsheetsplates.com.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

| SS 304L | 1.4306 / 1.4307 | S30403 | SUS 304L | – | 03Х18Н11 | Z3CN18‐10 | X2CrNi18-9 / X2CrNi19-11 |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | – | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

| Description | Process | G kg/m | h mm | b mm | tw mm | tf mm | r1 mm | r2 mm |

|---|---|---|---|---|---|---|---|---|

| C 50X25X5X6 | Hot Rolled | 3.95 | 50 | 25 | 5 | 6 | 6 | 3 |

| C 75X40X5X7 | Hot Rolled/Laser | 6.95 | 75 | 40 | 5 | 7 | 8 | 4 |

| C 100X50X5X7.5 | Hot Rolled/Laser | 9.37 | 100 | 50 | 5 | 7.5 | 8 | 4 |

| C 125X65X6X8 | Hot Rolled/Laser | 13.4 | 125 | 65 | 6 | 8 | 8 | 4 |

| C 150X75X6.5X10 | Hot Rolled/Laser | 18.62 | 150 | 75 | 6.5 | 10 | 10 | 5 |

| C 150X75X9X12.5 | Hot Rolled/Laser | 24.01 | 150 | 75 | 9 | 12.5 | 5 | 1 |

| C 180X75X7X10.5 | Hot Rolled/Laser | 21.52 | 180 | 75 | 7 | 10 | 2 | 1 |

| C 200X80X7.5X11 | Hot Rolled/Laser | 24.77 | 200 | 80 | 7.5 | 11 | 2 | 1 |

| C 200X90X8X13.5 | Hot Rolled/Laser | 30.53 | 200 | 90 | 8 | 13.5 | 2 | 1 |

| C 230X80X8X12 | Hot Rolled/Laser | 28.56 | 230 | 80 | 8 | 12 | 2 | 1 |

| C 250X90X9X13 | Hot Rolled/Laser | 34.86 | 250 | 90 | 9 | 13 | 2 | 1 |

| C 250X90X11X14.5 | Hot Rolled/Laser | 40.34 | 250 | 90 | 11 | 14.5 | 2 | 1 |

| C 300X90X9X12 | Hot Rolled/Laser | 37.17 | 300 | 90 | 9 | 12 | 2 | 1 |

| C 300X90X10X15.5 | Hot Rolled/Laser | 43.85 | 300 | 90 | 10 | 15.5 | 2 | 1 |

| C 300X90X12X16 | Hot Rolled/Laser | 48.78 | 300 | 90 | 12 | 16 | 2 | 1 |

| C 380X100X10.5X16 | Hot Rolled/Laser | 54.85 | 380 | 100 | 10.5 | 16 | 2 | 1 |

| C 380X100X13X16.5 | Hot Rolled/Laser | 62.5 | 380 | 100 | 13 | 16.5 | 2 | 1 |

| C 380X100X13X20 | Hot Rolled/Laser | 67.37 | 380 | 100 | 13 | 20 | 2 | 1 |

Industries that require high-temperature resistance, structural strength, and corrosion protection widely utilize Stainless Steel 310 Channels. In power generation, you’ll find them in furnace supports, boiler frameworks, and superheater components. The chemical and petrochemical sectors rely on them for high-temperature process equipment, heat exchangers, and structural supports. Additionally, industrial furnaces, kilns, and thermal processing equipment often use 310 channels for both structural and protective applications. Their unique blend of thermal stability and corrosion resistance makes them an essential choice for demanding environments.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Discover high-quality products tailored to meet your unique needs and preferences.

Get instant quotes that fit your budget perfectly.

Copyright 2024 Yunus Sheet and Plates. All rights reserved